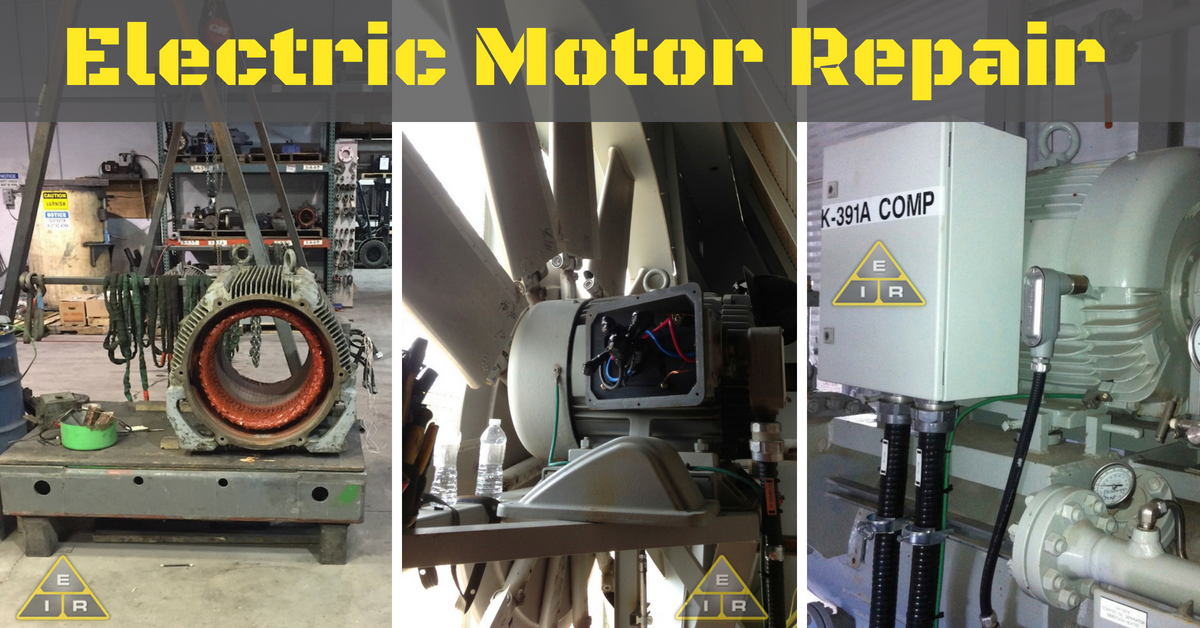

Electric Motor Repair for Electricians

Before you can repair an electric motor, you have to understand how the motor is built and how it works. A basic electric motor is a 120 volt, 4 pole permanent magnet motor with double insulation. The armature is supported by a ball bearing and needle bearing on the moving part of the electrical switch (commutator).

The four pin connector supplies the full wave bridge rectifier with 120 volts of AC power. This rectifier then provides 120 volts of DC power to the armature of the motor. The four pin connector is also responsible for the dynamic braking, capable of stopping the armature within just a few seconds.

How the Motor Works

The motor housing assembly has two ceramic magnets. Each magnet has a north and a south polar magnetic force, creating a four pole magnetic field. Inside the armature there are twenty-four coils, each one connected to its own commutator bar within the magnetic field in the housing of the motor.

When the current flows through the coil, a magnetic force is created. One side of the magnetic force flows in the same direction as the field within the housing, while on the other side a force is created that flows in the opposite direction. This produces a pulling up and down action on the coils, causing the armature to rotate.

Dynamic Braking

For added safety, an electric motor is equipped with a dynamic braking system. This is a feature of the electrical circuitry inside the handle switch, wire harness and motor. When the handle switch is released, it goes into the OFF position. This activates the dynamic brake by completing a separate circuit which reverses the magnetic force inside the armature, helping the motor come to a complete stop.

Electric Motor Repair: Care and Maintaining an Electric Motor

Improper care and maintenance is the biggest cause of motor malfunctions. Using an electric lawnmower motor as an example, the first thing you should do is make sure grass or other debris isn't clogging the air cooling system.

Once a year – a good time is in the spring before grass cutting season begins – remove the motor cover and wash the filter and the areas underneath with soapy water. Clean all the other parts of the motor with a dry cloth or brush. This will prevent the motor from overheating, which cause more serious damage.

Lubrication is generally not needed,

but if the motor bearings appear especially dry, a little oil might

not hurt.

This type of motor should only be used with 120 volt AC power. Any two conductor cord will work just fine. You don't need to ground the cord. Using an extension cord will cause the motor to lose some power, so don't use a longer cord than necessary.

Never clean or work on the motor when it is running. Make sure it is turned off and unplugged before starting any work.

Electric Motor Repair: Disassembling an Electric Motor

Make sure the motor is turned off and unplugged before you begin.

Remove the motor cover by taking off the two nuts and washers. This step is optional because not all motors have a cover.

Remove the brush end cap by prying up the three retaining tabs. Then remove the brush box by undoing the two nuts. The brushes and springs inside will come off with the box.

Remove the nuts holding the brush end cap, and take out the brush holders by releasing the spring tension. Remove the group of motor leads, the brushes and the rectifier as one unit. Disconnect the wires from the rectifier by pulling the spade connectors straight out to avoid damaging the terminals.

Remove the armature, insulators, retainer ring and the motor housing. Finally, remove the fan from the armature.

Check all the parts for visual damage, excessive rust and corrosion. Damaged parts should be replaced. Rust and corrosion can be removed with a wire brush. In most cases, the brushes will have to be replaced.

Electric Motor Repair: Testing

To check the electrical components, use a digital multimeter. It will check the volts, ohm's and ampere of the motor. It can also be used to check the diodes. Use a tachometer to check the revolutions per minute.

A Hi-Pot tester is recommended to detect a breakdown in the insulation, which can cause a severe to fatal electrical shock.

Electric Motor Repair: Troubleshooting

Motor won't start:

Check the power supply. There could be a problem with the outlet or the extension cord.

Make sure the rectifier is closed.

Check the controller for an open circuit, tripped circuit breaker or not enough lever travel.

Make sure the armature is closed.

Check for worn or sticking brushes.

Motor seems to lag:

Check for excessive load, clogging or other obstructions.

Dirty or corroded electrical connections.

Dirty or worn commutator.

Motor trips circuit breakers, runs hot or smokes:

Usually caused by a short in the rectifier, motor, armature or extension cord.

Overloading the circuit with other appliances.

Electric motors generally have a very long life span. With proper care and maintenance, you can extend this by several years.